1. Introduction to Manual Powder Coating Machine Systems

A Manual Powder Coating Machine System is a user-operated setup designed for applying dry powder coatings to metal surfaces. Key components include a handheld electrostatic gun, powder hopper, control unit, and grounding system. These systems are ideal for small workshops, custom projects, or low-volume production, offering flexibility and affordability compared to automated alternatives.

2. Applications of Manual Powder Coating Machine Systems

Commonly used in automotive repair, metal fabrication, furniture restoration, and DIY projects. They coat items like tools, bike frames, small machinery parts, and decorative metalwork. Manual systems suit businesses requiring custom powder coating solutions without high-volume demands.

3. Pricing of Manual Powder Coating Machine Systems

Manual systems for sale typically cost between 1,000and10,000. Basic kits (gun + hopper) start at 1,000–3,000, while advanced setups with curing ovens and recovery systems reach 5,000–10,000. Refurbished models offer budget-friendly options for startups.

4. How to Use a Manual Powder Coating Machine System

Clean surfaces thoroughly to remove contaminants. Adjust the gun’s voltage (30–80 kV) and maintain a 6–12 inch spray distance. Apply powder in even, overlapping strokes. Cure coated parts in an oven (300–400°F) for 10–20 minutes. Clean the gun and hopper after each use to prevent clogs.

5. Choosing a Manual Powder Coating Machine System for Sale

Prioritize ergonomic gun designs to reduce operator fatigue. Ensure voltage adjustability for different powder types. Look for easy-to-clean components and compatibility with small ovens. Check warranties and vendor support for durable manual coating equipment.

6. Safety Tips for Manual Powder Coating Systems

Operators must wear PPE (respirators, gloves, goggles) to avoid inhaling particles. Ground the workpiece and equipment to prevent electrostatic discharge. Work in ventilated areas and avoid open flames near powder residues.

7. Cost Efficiency of Manual Powder Coating Systems

Manual systems minimize upfront costs and energy consumption, making them ideal for low-budget coating projects. Their simplicity reduces maintenance expenses, while compact designs save workspace.

8. FAQs About Manual Powder Coating Systems

Q: How long does a manual system last?

A: With proper care, 5–8 years, suitable for small-scale powder coating tasks.

Q: Can manual guns coat large parts?

A: Yes, but multiple passes may be needed for uniform manual spray coverage.

Q: Are these systems eco-friendly?

A: Yes, they produce minimal waste and use VOC-free powder materials.

Q: How to fix uneven coating?

A: Check grounding, adjust spray distance, and ensure consistent powder flow settings.

Q: Do manual systems include curing ovens?

A: Some packages include compact ovens, but standalone units are also available.

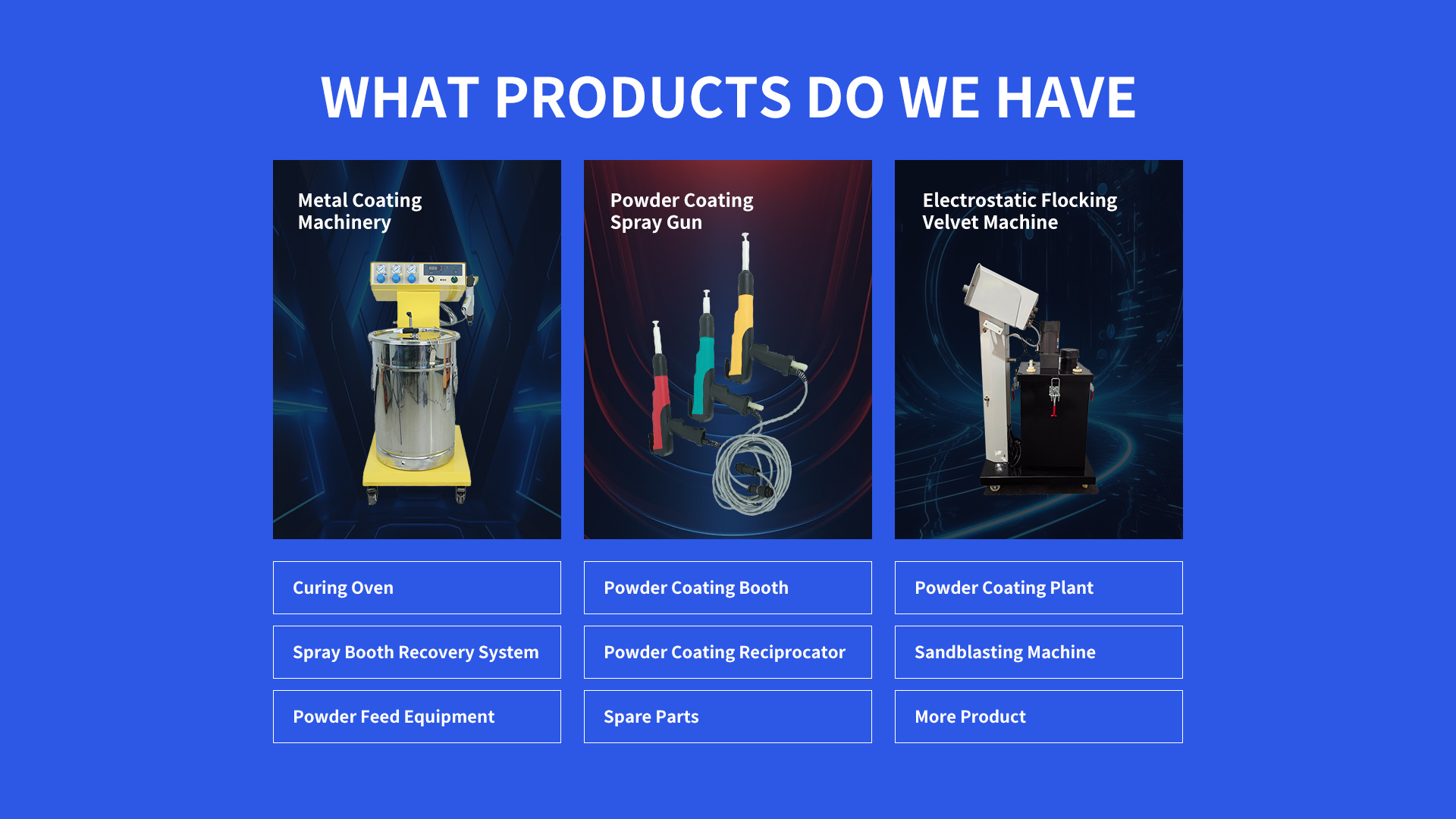

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com